Here is a brief description of some of the woods that are commonly used in woodworking.

The selection of wood for each project should be made with care, as each kind of wood has its own peculiar color, working qualities, and properties.

1. Ash

The three most common types of ash are White, green, and black.

White ash is very common in furniture construction; it has a wide use in sports equipment such as skis, baseball bats, and toboggans.

It is well suited to these uses because of its strength and hardness but particularly because it holds its shape well after it has been formed.

2. Basswood

Softest of commercial hardwoods, basswood is white with a few black streaks, fuzzy because of long fibers, fairly strong for bending, non-warping, with little or no grain marking.

Basswood is the best wood for drawing boards, for small moldings, for burned designs, and for thin lumber for jigsaw work. It is not durable for outside uses.

It makes a very strong glue joint and is easy to plane or sand but does not scrape well because of its long fibers and yielding surface. It is usually painted but may be stained to imitate other woods.

3. Birch

Birch is a hardwood of fine texture and close grain, coming primarily from the north central states and Canada.

Yellow birch is the most common.

Curly birch is found only in occasional trees, the result of a rare grain development.

It has a delicate, wavy figure and is sought for fine furniture and panels. It is difficult to work and must be finished by scraping.

The heartwood is red in color and the sapwood is white and therefore a single board may be either red or white or red with white edges. It is a good wood for table tops, doors, rails, and any furniture parts which require extra strength.

Birch will take practically any desired color of stain and is one of the finest woods for enamel finishes.

It is sometimes finished to resemble mahogany, walnut, or maple.

4. Red cedar

There are many kinds of cedar that vary in color from white to deep red.

The red cedar most commonly used for making chests and lining drawers and closets comes from Tennessee.

Cedar is a softwood with a very distinctive odor.

It is one of the simplest woods to identify.

Because of its odor, which makes it moth—repellent, it is a good liner for closets in which woolens are stored.

5. Cherry

Black cherry, which is found generally in most parts of the United States, is not abundant enough to be a common furniture wood, even though it is a very desirable wood for that purpose.

The heartwood is a reddish brown in color, while the sapwood is white.

Cherry resembles unfinished mahogany.

It is a very durable wood, does not dent easily, and warps very little.

There are many heirlooms of genuine cherry, indicating that it was more common many years ago.

Cherry darkens with age.

It is best finished with shellac or lacquer and because of this has a natural suitability to modern as well as period furniture.

6. Red Cypress

Red cypress, which comes from Louisiana swamps, is softer grained, darker colored, and more durable than the upland or yellow cypress.

For boats, lawn furniture, and outdoor use, it has always been durable and popular.

The grain is rather hard, making the wood splinter easily.

7. Gumwood

Gumwood is a native of the deltas of the rivers throughout the south.

Because of its tendency to warp in seasoning, gumwood was not commonly used for many years as a distinctive commercial wood.

Previously, when it was used at all, it was finished to imitate some other type of wood.

At the present time, it is recognized as a wood of great beauty and a wide range of usefulness.

The heartwood, which is called red gum, ranges from a light to a deep reddish brown.

The sap-wood is light colored and is referred to as a sap gum.

While gum-wood is considered by its producers a hardwood, it really is a medium hardwood, not so hard as maple and harder than many pines.

Fine furniture and trim are made from gumwood.

It is one of our most decorative woods.

One of its unusual features is that no two long boards produce the same figure in the wood.

The wood is close grained and has a verv fine texture.

Gumwood is either plain—sawed, quarter-sawed, or veneered.

Selected gumwood finishes very well in the natural color, but best results are produced when it is given a light brown stain.

Where light streaks appear next to the dark, it is good practice to give the light wood a thin preparatory coat, wipe it off, and then give the entire surface a separate coat.

Water stains should always be chosen for gumwood, though these have a tendency to raise the grain.

This means that a light sanding is required before the succeeding finishing can be done.

The beauty of gumwood is better preserved by a dull treatment than by a gloss or polished finish.

Dull lacquer, dull varnish, or hand-rubbed varnish produces the best effect on either interior trim or furniture.

Because of its coarse grain, gumwood makes an excellent foundation for an enameled finish.

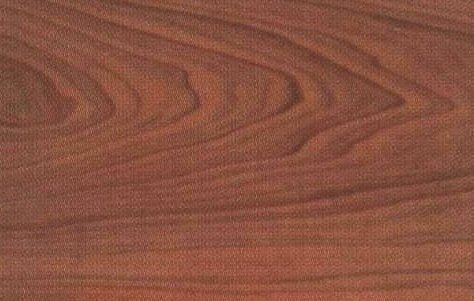

8. Mahogany

Mahogany, which is a soft, open-grained wood, is considered one of the finest furniture woods we have.

It is often preferred because of its pleasing figure, its density or weight, its low shrinkage characteristics, and its ease of working.

Mahogany comes from many countries and is frequently identified by the name of the country—for example, Honduras Mahogany.

The color of mahogany varies from white to light brown.

It is a very beautiful wood in its natural state and can be finished either as a darker wood for traditional furniture or bleached for modern pieces.

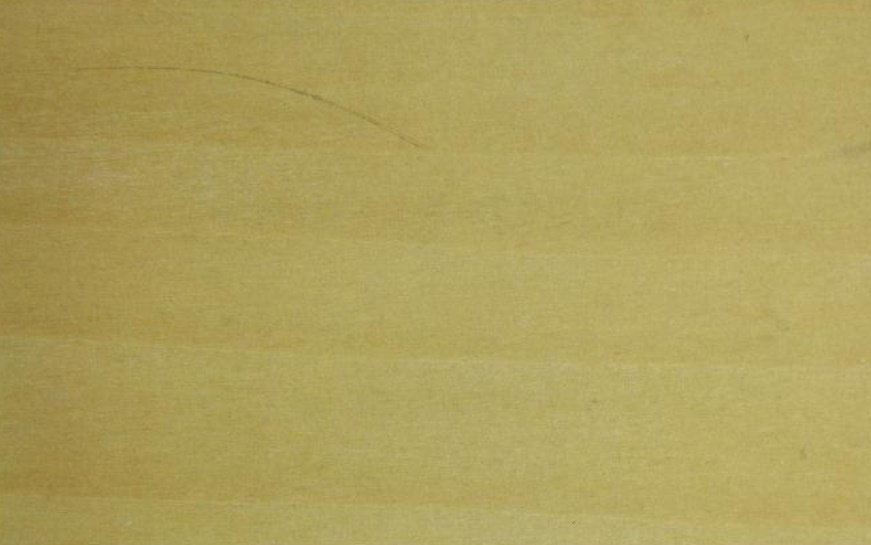

9. Maple

Maple is a hard, tough, strong wood that has good resistance to shock and wears very well.

The grain is usually straight and fine in texture.

The heartwood of maple is light reddish brown and its sap-wood is white.

Because of its wear-resisting qualities, maple is ideal for fine flooring.

It is found very extensively in Colonial furniture and also in modern design.

A white, clear grade of maple, which comes from the sapwood, is especially light.

It is the white wood which can be made into furniture and for the finer floors on which natural finish is to be used.

The heartwood is brown and makes a good base for a brown, mahogany, or dark stain.

Curly maple is the result of a twisted growth and the manner in which the lumber is sawed.

Bird’s-eye maple is cut from sugar maple trees and the texture is a result probably of thwarted bud growth.

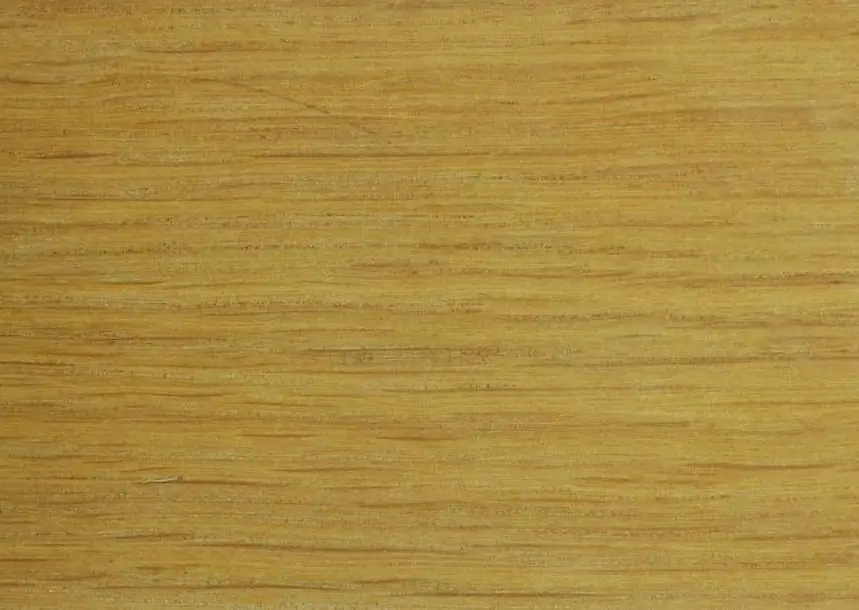

10. Oak

Oak has always been one of the most popular cabinet woods.

Now and then one or more woods come into vogue for a few years but there is always a sure return to oak.

The reason for this is the lasting qualities, the durability, permanence, and the appearance of strength and solidity that oak possesses.

Oak is very beautiful in its natural state and this beauty is intensified by a greater variety of finishes that can be applied to it than to any other wood.

It is an international wood, found in many countries, and is the leading hardwood of North America.

There are nearly 300 kinds of oak in the United States, but from the woodworker’s standpoint there are only two, white and red.

White oak has a better color, finer texture, and more prominent figure.

It is considered a superior wood for fine furniture.

Red oak, however, because of its slightly reddish tinge and because it is coarser in grain, can be used very successfully to secure desired decorative effects.

Oak is cut in two ways, plane-sawed and quarter—sawed.

Quarter sawing reveals the distinctive characteristics of oak.

Because of its open grain, oak offers a greater opportunity for the use of fillers which contrast with stains than is offered by any other wood.

11. White Pine

There are many kinds of white pines, but the ones most commonly selected for work in the woodshop are the northern white, ponderosa, sugar or California, and western white or Idaho pine.

All have the same general characteristics, although they differ slightly in color, texture, hardness, and working qualities.

White pine has a soft, uniform texture that makes it an ideal building- material.

The sapwood is white and the heartwood ranges from cream to light reddish brown.

White pine is used for mill-work, building construction, window frames, doors, and interior trim.

Pine does not swell or shrink with the change in moisture, which makes it ideal for patterns.

It is the equal of any wood and superior to most of them as a foundation for paint or enamel finishes.

White pine is not a desirable wood for most stain finishes, although selected boards having markings more pronounced than average can be stained with light mahogany or light brown stains.

12. Yellow Poplar

Poplar is a durable, soft, medium strong hardwood.

It is one of the largest native trees supplying lumber.

The sapwood, which is frequently several inches thick, is white, while the heartwood is yellowish brown with a green tinge.

The wood is moderately light in weight, straight grained, uniform in texture, easy to nail because it doesnot split readily, easy to glue, stays in place well, holds paint and enamels well, is easily worked, and finishes smoothly.

Because of all these qualities, it is very satisfactory for inexpensive furniture that is to be painted and enameled.

It is also a very suitable wood for beginners to choose.

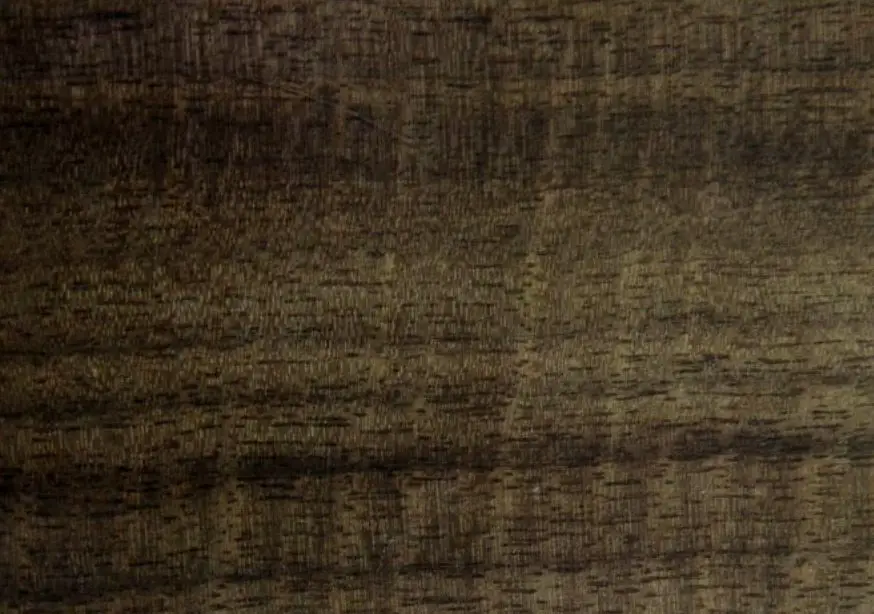

13. Walnut

Walnut, a medium hardwood that is one of the most beautiful native woods, is found in the eastern half of the United States.

The heart-wood is brown, while the sapwood is nearly white.

Walnut is a strong, durable, and stiff wood.

It is used chiefly for cabinetwork, furniture, veneers, and gunstocks.

The veneer is cut from the best grade walnut and is made into panel stock and plywood.

Walnut is excellent for cabinetwork because it works well, glues up very satisfactorily, and takes a good finish.

Walnut is usually finished in the natural wood.

It is an open—grained wood and requires a filler.

Usually the filler is very dark, but at times a lighter filler is applied for constrast.

The wood is finished with a high-gloss varnish that is frequently rubbed to a high polish.