Forstner bits are high-quality cutting tools that are used for making precise, flat-bottomed holes in wood and other materials.

The speed at which you should use a Forstner bit depends on several factors, including the type and thickness of the material you are cutting, the size of the bit, and the power of your drill.

In general, you should use a slower speed when cutting with a Forstner bit to help ensure that the cutting edges stay cool and to reduce the risk of the bit overheating or breaking.

It’s also a good idea to use a low torque setting on your drill when working with Forstner bits, as this can help to reduce the risk of the bit binding or breaking.

If you are not sure what speed to use, it’s always a good idea to start slow and gradually increase the speed if needed.

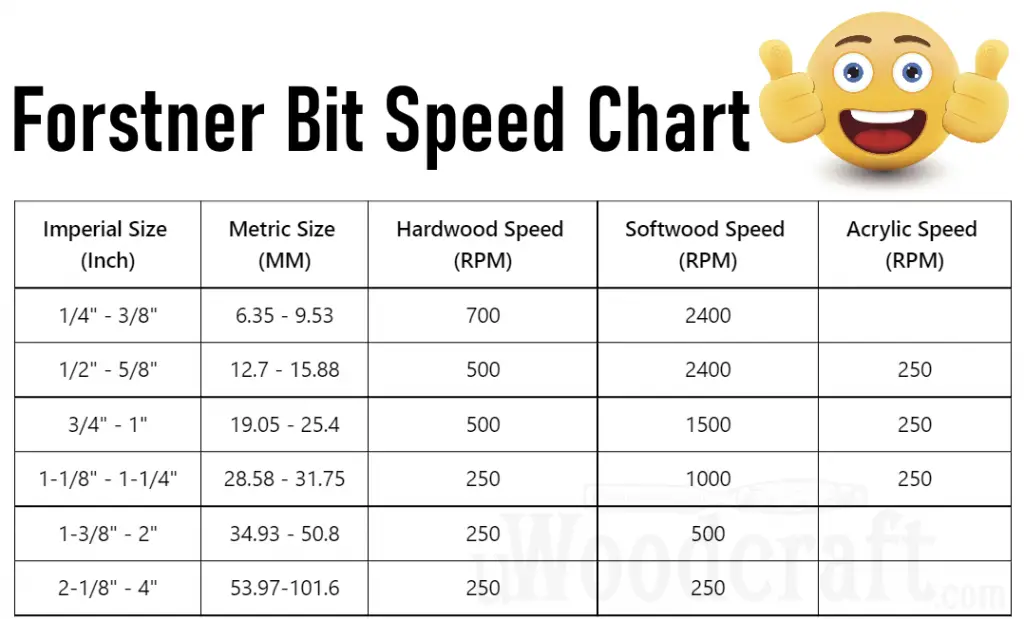

Forstner Bit RPM Speed Chart (Text Version)

| Imperial Size (Inch) | Metric Size (MM) | Hardwood Speed (RPM) | Softwood Speed (RPM) | Acrylic Speed (RPM) |

| 1/4″ – 3/8″ | 6.35 – 9.53 | 700 | 2400 | |

| 1/2″ – 5/8″ | 12.7 – 15.88 | 500 | 2400 | 250 |

| 3/4″ – 1″ | 19.05 – 25.4 | 500 | 1500 | 250 |

| 1-1/8″ – 1-1/4″ | 28.58 – 31.75 | 250 | 1000 | 250 |

| 1-3/8″ – 2″ | 34.93 – 50.8 | 250 | 500 | |

| 2-1/8″ – 4″ | 53.97-101.6 | 250 | 250 |

Forstner Bit RPM Speed Chart (Image Version)

Here’s the same chart as above but in image format for easier printing/sharing/etc.

What is a Forstner Bit?

A Forstner bit is a type of woodworking drill bit that is designed for boring precise, flat-bottomed holes in wood. It is named after its inventor, August Forstner, who patented the design in the late 19th century.

Unlike twist drill bits, which have a point that cuts into the material and a helical flute that removes the chips, Forstner bits have a flat end and a series of small, flat cutting edges around the circumference of the bit.

This design allows them to cut a clean, flat-bottomed hole with little or no tear-out on the back side of the workpiece.

Forstner bits are available in a range of sizes and are typically used in woodworking and carpentry to create holes for dowels, screws, and other fasteners, as well as to create mortises and other joinery.

They can also be used to create decorative inlays and to drill partially through a piece of wood to create a stopped hole.

Forstner bits are typically used with a drill press, but can also be used with a hand-held drill if care is taken to keep the bit straight and to apply a steady, even pressure.

They are generally made of high-speed steel or carbide and are sharpened using a bench grinder or other sharpening tool.

Can you use a Forstner bit in a hand drill? Or a drill press?

Yes, you can use a Forstner bit in a hand drill or a drill press.

Forstner bits are special types of drill bits that are designed for creating precise, flat-bottomed holes in wood. They are commonly used for doweling, hinge installation, and other woodworking tasks.

To use a Forstner bit in a drill, you will need a drill press or a hand drill with a chuck that is capable of holding the bit securely.

It is important to use the correct size Forstner bit for the task at hand, and to use it at the proper speed and with the correct feed rate to avoid damaging the bit or the workpiece.

It is also a good idea to use a drill press or a hand drill with a depth stop to ensure that you do not drill too deeply into the workpiece.

When to use a Forstner Bit

Forstner bits are commonly used for woodworking tasks that require precise, flat-bottomed holes. Some examples of tasks where Forstner bits are often used include:

- Doweling: Forstner bits can be used to create precise, flat-bottomed holes for dowels, which are used to join two pieces of wood together.

- Hinge installation: Forstner bits can be used to create the holes needed to install hinges on doors and other woodworking projects.

- Mortise and tenon joints: Forstner bits can be used to create the mortises (recesses) needed for mortise and tenon joints, which are strong, traditional woodworking joints used to join two pieces of wood together.

- Boring out waste material: Forstner bits can be used to bore out waste material from the center of a workpiece, creating a precise, flat-bottomed hole.

- Drilling through thin material: Forstner bits are well-suited for drilling through thin materials such as plywood, as they are less likely to splinter the wood.

Overall, Forstner bits are a useful tool for a wide range of woodworking tasks where precise, flat-bottomed holes are needed. They are particularly well-suited for tasks where a clean, smooth finish is desired, and they can be used in a drill press, hand drill, or router to achieve good results.