One of the last steps before assembling a project is sanding.

All planing, cutting, and forming should be completed before beginning to use sandpaper.

Sanding is done only to finish the surface of wood and not to form or shape it.

Too frequently sandpaper is used in place of cutting tools.

Contents

Types of Sandpaper

There is really no such thing as “sand” paper, though the name is given to two types of abrasives:

- Flint which has a yellowish cast and

- Garnet which is tawny red.

For hand sanding, the flint paper is often used, even though garnet is harder, sharper, and better for most woods, especially hard woods.

Sandpaper is made by applying a coat of animal glue to a tough paper and then coating the surface with the flint or garnet.

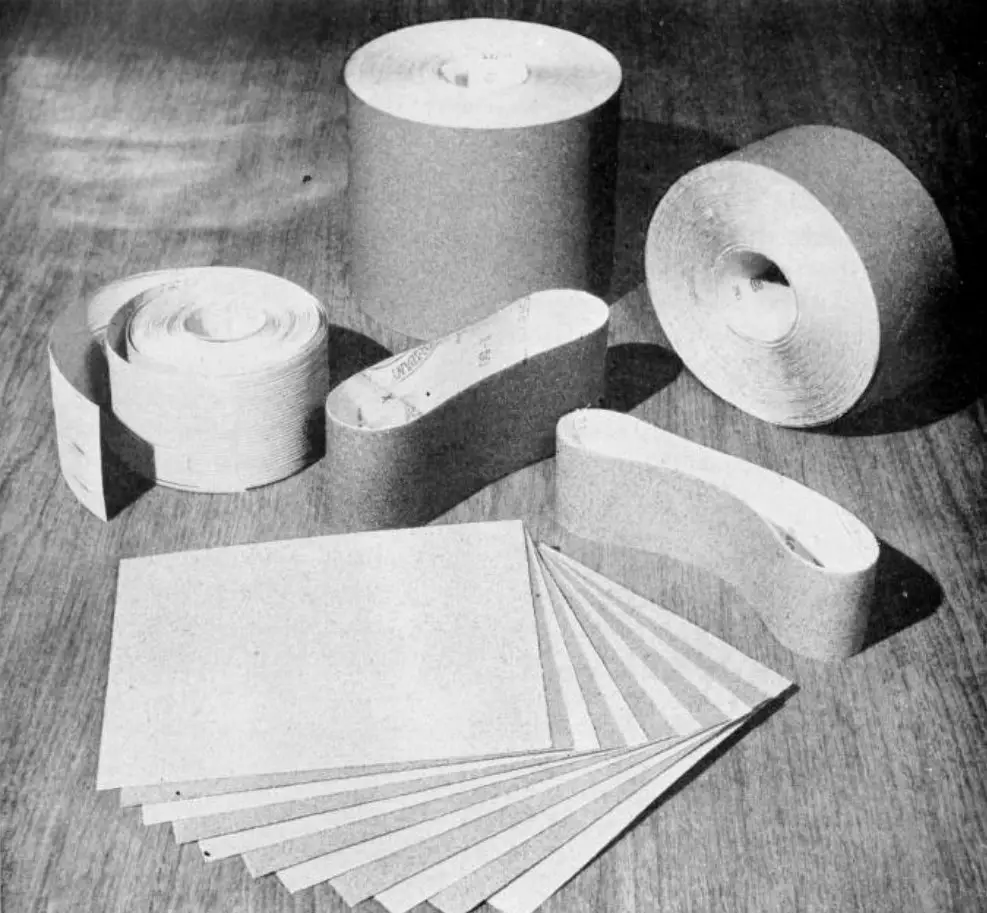

Sandpaper is usually sold in 9″ or 11″ sheets in quires (24) or reams (144).

The paper ranges from No. 3 or 3 1/2 (very coarse) to No. 7/0 or 8/0 (very fine).

You will find that about three different coarseness grades of paper, No. 0 (fine), No. 1/2 (medium), and No. 1 (coarse) will be enough for most jobs.

Tearing Sandpaper

To make the sheet of sandpaper more flexible, draw it over the edge of the bench.

A 9″ x 11″ sheet is usually divided into four or six pieces depending upon the kind of work to be sanded and the size of your sanding block.

To tear the sheet, fold it lengthwise with the abrasive surface toward the inside, then hold one half of the sheet over the bench and tear the paper along the folded line.

Sometimes you can tear the piece by holding a straight-end or the cutting edge of a saw over the folded line.

The Sandpaper Block

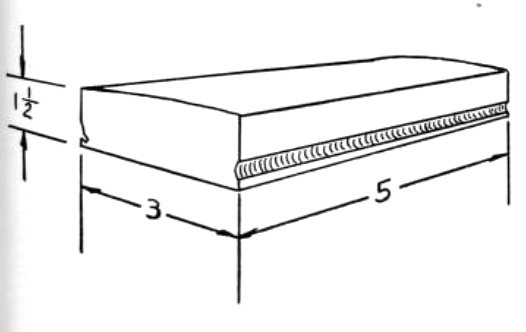

For most sanding, a sandpaper block is a good backing.

If the sheets are torn into six pieces, a block 1 1/2″ thick, 3″ wide, and 5″ works well.

A piece of foam rubber or felt can be glued to the base to provide a more flexible surface.

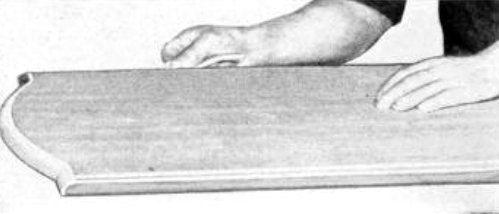

Sanding a Flat Surface

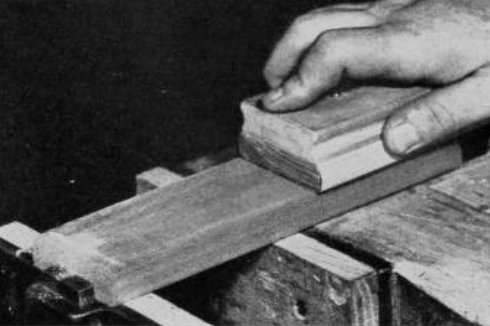

Fasten the piece between the vise dog and bench stop or hold it firmly against the surface of the bench.

If the piece is held in the vise, grip the sanding block.

Apply even pressure to the block and sand the surface with the grain of the wood.

Move the block back and forth and work slowly from one side to the other to obtain an even surface.

Take special care to keep from sanding the edges too much.

After the coarser paper has been used, finer grades are substituted to produce a progressively smoother finish.

If the piece is held against the top of the bench, you can operate the block with one hand.

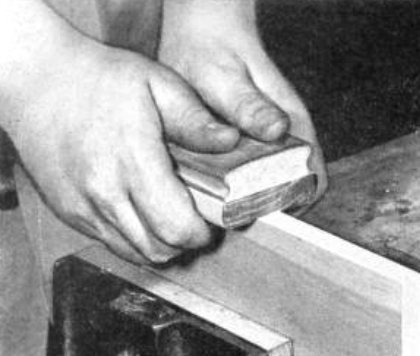

Sanding an Edge

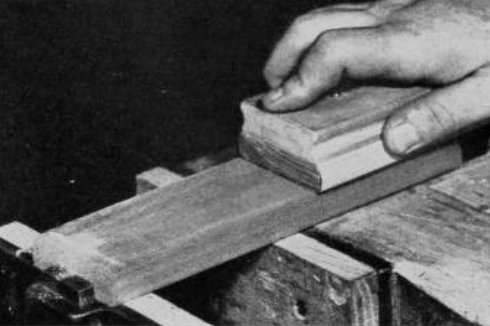

Lock the work in a vise with the edge exposed.

Grasp the sanding block in both hands, using the forefinger on either side of the edge to keep it square with the sides.

It is just as important to sand an edge square as it is to plane it square.

After the edge has been sanded, the arris is rounded slightly by drawing the paper over the edge.

Sanding an End

To sand the end of a piece, the same procedure as for sanding an edge is followed, except that the surface is sanded in only one direction rather than back and fourth.

This produces a smoother finish.

Sanding Convex Surfaces

Convex surfaces can usually be sanded with a block in the same way an edge is sanded.

But convex surfaces such as rounded ends can be done more satisfactorily by holding the paper in the fingers or palm of your hand.

Sanding Concave and Other Inside Surfaces

These surfaces are most easily finished by wrapping the paper around a stick such as part of a broomstick or the handle of a tool.

The half-round surface of a file also makes a suitable backing.

Scraping a Wood Surface

When is Scraping Used?

To obtain a really fine surface on open grain wood such as oak, mahogany, and walnut, the wood is frequently scraped after the planing is done.

This scraping removes the small irregularities that have been left there by the plane iron.

Some wood, such as curly maple and cedar, that cannot be planed successfully, can be scraped to produce a very smooth surface.

It is very important to have a sharp hand scraper.

It is always necessary to sharpen the scraper before each time it is used and frequently during its use.

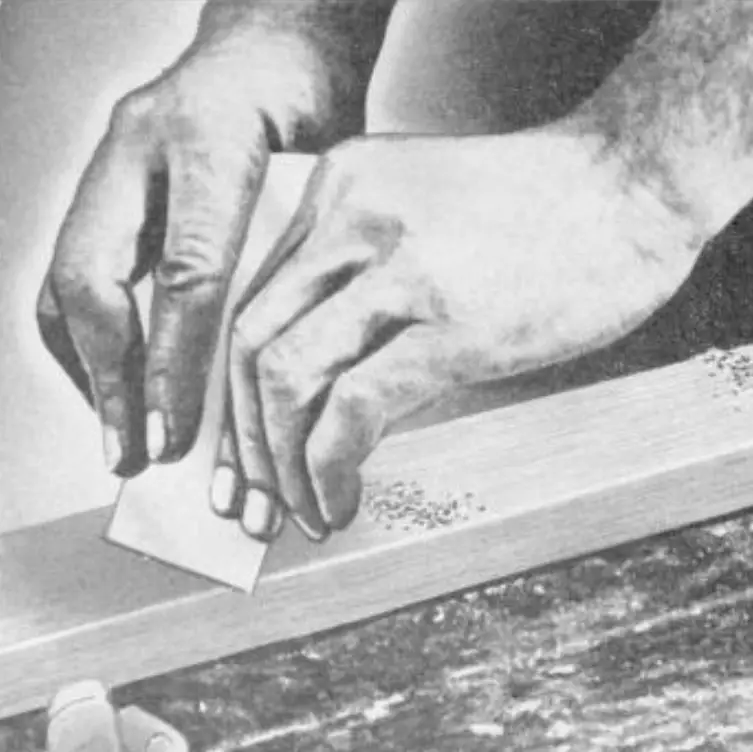

How to Scrape a Wood Surface?

Clamp the stock firmly in a vise or on top of the bench.

Hold the hand scraper with both hands between the thumbs and forefingers with the cutting edge toward the surface of the wood.

Turn the blade at an angle of about 50 to 60 degrees to the surface of the wood.

Apply firm pressure to the scraper blade and push or draw it across the surface.

Be careful to keep the cutting edge flat against the wood so that the corners do not dig in or mar the wood.

Always scrape with the grain of the wood.

Sometimes the scraper is turned a little and a shearing cut made across the surface.

IF you are working on curly maple or other burly type wood, always change the direction of the scraping action to correspond with the direction of the grain.

Wood Surface Sanding Review Questions

- Is sanding used for forming or shaping wood?

- At what point in the building of a project should sanding be done?

- Is there any sand in sand paper?

- What are the two abrasives used in sandpaper?

- Which sandpaper is best for hardwood? For softwood?

- How is sandpaper usually sold?

- What number would you ask for when buying very coarse sandpaper? What about for very fine?

- What are the 3 most common grades of sandpaper?

- How would use soften a sheet of sandpaper before using it?

- How would you tear it into smaller pieces?

- How is a sanding block useful?

- How can you keep the edge square when sanding?

- How would you sand a convex surface?

- How would you save a concave surface?

- On what kinds of wood is scraping necessary to produce a smooth surface?

- At what times should a scraper be sharpened?

- The scraper is held at what angle to the surface of the wood?

- How can you prevent the corners of the scraper from marring or digging into the wood?

- How should the scraper be used on burly woods?