The most common Taper in use on the Lathe is the Morse Taper.

Although there are many other types of Taper in use, these are generally for use in Mechanical and Precision Engineering Disciplines, such as Collet Chucks for Milling, and therefore not often encountered by the Woodturner.

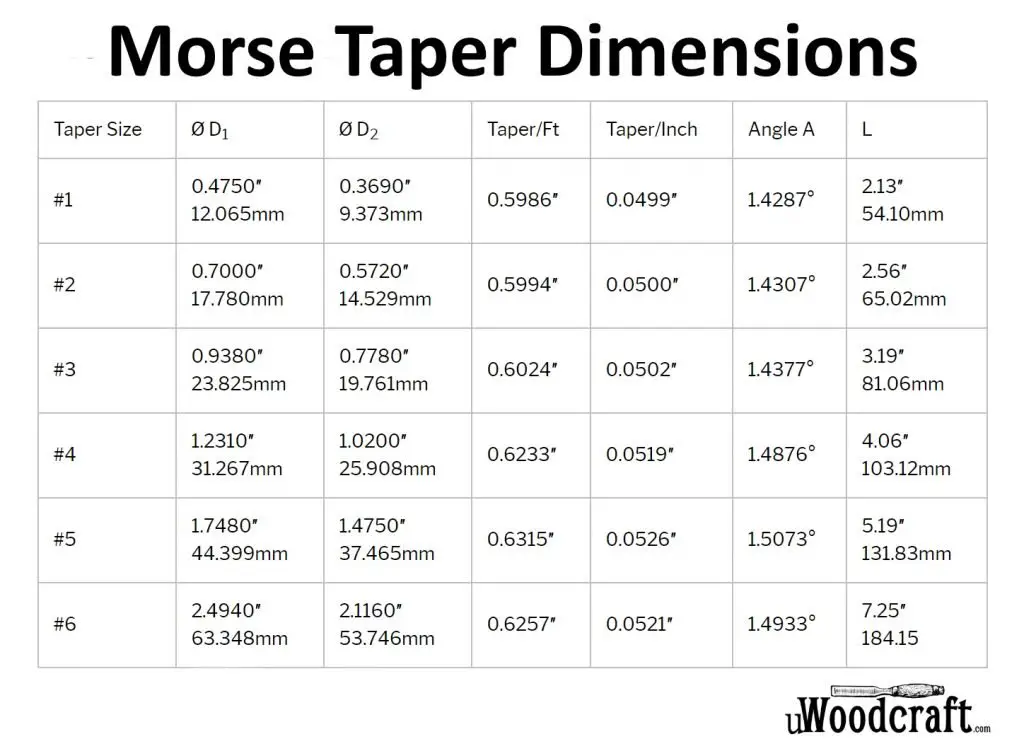

Morse Taper Dimensions Table

The Standard Dimensions for the various Sizes of the Morse Taper Shank are given below.

| Taper Size | Ø D1 | Ø D2 | Taper/Ft | Taper/Inch | Angle A | L |

| #1 | 0.4750″ 12.065mm | 0.3690″ 9.373mm | 0.5986″ | 0.0499″ | 1.4287° | 2.13″ 54.10mm |

| #2 | 0.7000″ 17.780mm | 0.5720″ 14.529mm | 0.5994″ | 0.0500″ | 1.4307° | 2.56″ 65.02mm |

| #3 | 0.9380″ 23.825mm | 0.7780″ 19.761mm | 0.6024″ | 0.0502″ | 1.4377° | 3.19″ 81.06mm |

| #4 | 1.2310″ 31.267mm | 1.0200″ 25.908mm | 0.6233″ | 0.0519″ | 1.4876° | 4.06″ 103.12mm |

| #5 | 1.7480″ 44.399mm | 1.4750″ 37.465mm | 0.6315″ | 0.0526″ | 1.5073° | 5.19″ 131.83mm |

| #6 | 2.4940″ 63.348mm | 2.1160″ 53.746mm | 0.6257″ | 0.0521″ | 1.4933° | 7.25″ 184.15 |

All dimensions are in inches with Metric [mm] equivalents for major dimensions.

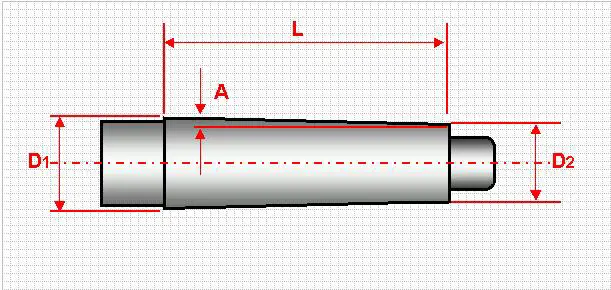

D1 = Large End of Taper Diameter.

D2 = Small End of Taper Diameter.

A = Angle of Taper. (Morse Taper Angle in Degrees)

L = Length of Morse Taper Section.

The Overall Length of the Morse Taper will depend on individual designs from the Manufacturers.

Morse Taper Dimensions Chart in Image Format

Here’s the same table as above but in image format for easier sharing/printing:

How to Measure a Morse Taper

To identify the size of a Morse taper, you can use a Morse taper gauge or a set of Morse taper shanks.

A Morse taper gauge is a tool that is designed specifically for measuring the size of a Morse taper.

It consists of a series of pins with tapered ends that match the various sizes of Morse tapers.

To use a Morse taper gauge, you simply insert the appropriate pin into the taper and see how far it goes in.

The size of the taper is determined by the pin that fits the best.

Alternatively, you can use a set of Morse taper shanks to determine the size of a Morse taper.

Morse taper shanks are tapered rods that are designed to fit into a Morse taper.

Each shank is labeled with the size of the taper that it fits.

To use a set of Morse taper shanks, you simply try each shank in the taper until you find the one that fits the best.

The size of the taper is determined by the shank that fits the best.

It is important to note that both of these methods only work if the Morse taper is undamaged and in good condition.

If the taper is damaged or worn, it may not fit the gauge or shanks correctly, and the size may be difficult to determine.

In this case, it may be necessary to measure the taper directly using a caliper or other precision measuring tool.

Checking the Morse Taper Size

The following is a video on how to measure your morse taper by after removing the chuck of the drill press:

Morse Cone Dimensions

A Morse cone is a type of mechanical component that is used to transmit power between two shafts that are not collinear.

It consists of a tapered sleeve that fits over a tapered shaft, with a flange on one end that is used to secure the cone in place.

The dimensions of a Morse cone will depend on the specific application and the size of the shafts that it is being used with.

Some common dimensions for Morse cones include:

- Diameter of the smaller end: This is the diameter of the end of the cone that fits over the smaller shaft. It is typically measured in millimeters or inches.

- Diameter of the larger end: This is the diameter of the end of the cone that fits over the larger shaft. It is typically measured in millimeters or inches.

- Length: This is the length of the cone, measured along the axis of the tapered shaft. It is typically measured in millimeters or inches.

- Taper: This is the rate at which the diameter of the cone increases or decreases along its length. It is typically expressed as a ratio, such as 1:10, which means that the diameter of the cone increases by 1 unit for every 10 units of length.

It is important to choose a Morse cone with the correct dimensions for your application to ensure that it fits properly and transmits power effectively.

Hello, I have an older Jet JWL1236 wood lathe on which the quill fits into an inside diameter of 1 1/8″. I would like to Install a morse tapar and a drill chuck to drill out vase work. Do you Carry the appropriate parts or might guide me in the right direction to fit into that opening? I tried instaling a M2 tapar but it was much too small.Thank you!!!