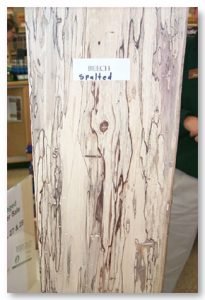

Spalted wood embodies all that is curious in the natural world.

It is held in esteem for its natural beauty by woodturners and craftsmen and in contempt by lumberman and sawmillers for its degradation.

But just what is it?

Spalted wood is a wood that, due to the presence of fungi, differs from its normal appearance and coloring. The visual qualities of spalted wood make it very desirable for certain woodcrafts.

What causes Spalting?

Spalting is caused by the infections of wood with various kinds of white-rot fungi.

The ideal conditions for spalting to take place are temperatures that range from 70 to 90 degrees Fahrenheit with a moisture content that is at or near the fiber saturation point of about 30%.

The characteristic blue-black zone lines of spalted wood form when incompatible colonies of fungi come into contact with each other and lay down barriers to separate their territories.

This phenomenon represents the early stages of the decay process.

This incipient decay may or may not seriously weaken the wood, although a gradual softening of the wood is apparent and accompanied by a gradual change in color to grayish-white.

In the later stages, the infected wood is of a dirty white color and becomes soft and spongy.

If a piece of decayed wood with zone lines is pulled apart very carefully, the zone line will be seen as a layer or sheet of dark rubbery material.

Which Woods are Susceptible to Spalting?

Spalting occurs in many species but most commonly in the birches, beeches, and maples.

Buckeye, elm, basswood, sycamore, and apple spalt, but it is relatively unknown in red and white oak.

Generally speaking, white woods with heartwood non-resistant to decay are good candidates for spalting.

Frequently, in sugar maple, the spalting lines are double, run parallel and appear somewhat concentric. The spalting process occurs at different rates for different woods and depends on climate and environmental factors.

The Availability of Spalted Wood

Because spalted wood is consistently inconsistent in appearance it is in high demand within the decorative wood markets.

Each piece is unique and completely different from the next.

One tree may have good workable spalted wood, while the next although appearing the same will be useless.

Only by working with spalted wood can one gain the knowledge necessary to succeed with and fully appreciate the challenges of this unpredictable material.

Judging the Quality of Spalted Wood

One paradox of spalted wood is that as it ages it gets to a certain point where it is more attractive to the artist and less attractive to the tradesman.

If the wood is found too early, it lacks character and seems bland when compared to spalted wood, but caught at the right stage of its life it is still stable and suitable for working and resists checking.

The lines of spalted wood can be so intricate that it looks as though they were penned by an ancient calligrapher.

By using a little imagination one can begin to see pictorial figures such as maps of the world, animals, birds, fish, and mountains.

The possibilities for spalted wood products are limited only by imagination and ingenuity.

Producing Spalted Wood

Producing spalted wood for the home workshop certainly is attainable although it is a hit or miss proposition if you are trying to obtain a particular level or type of spalting.

Under favorable conditions, the process takes only weeks or at most a few months.

The key to stimulating wood to spalt is providing the fungi with the kind of moist, warm environment in which they thrive.

The more taxing challenge is figuring out when to halt the process before the fungi decompose the wood to the point that it is no longer usable.

The simplest way to produce but the hardest way to control spalted wood is to put some logs into a shady woods, cover them with leaves and keep the pile moist.

For better control and for spalting smaller-sized material simply place the wood in plastic bags and keep moist.

This allows for easier inspection and control.

Fungi spores are so plentiful in the atmosphere that there is no need for inoculation and unfortunately no guarantee that the preferred spalt will occur.

Cautions of Working with Spalted Wood

The dust created from sanding and sawing spalted wood has a toxic nature about it and has a reputation for causing respiratory problems.

More specifically the mold or fungi that cause spalting to occur is what triggers the asthma-like reactions that can be severe.

Farmers handling moldy hay may experience similar symptoms.

About two to five percent of the population can be expected to develop an allergic sensitivity to one or more compounds found in wood.

If you handle a lot of potentially toxic species and work with them long enough, you increase your chances of a reaction.

Among hobby woodworkers, at least one death has been reported, that of a New Orleans man in 1987.

Spalted wood can also contain clostridium, the bacteria responsible for botulism.

The best defense is to have a good dust extractions system and to wear a dust mask when working with spalted or any other kind of wood.

Conclusion

Spalted wood has always been around; it might even be right in your own backyard, you probably wouldn’t have to go too far to find it.

Go out and look for it, by discovering and recognizing the potential and limitations of this material one can develop a better appreciation for the duality of life and its curious nature.