A screen with a hole in it is guaranteed to attract bugs, but the repair is an easy one.

Fixing a Damaged Screen

This section is for fixing a screen with a small tear.

Fiberglass Screen

Close tiny holes in a fiberglass screen with a dab of clear nail polish or household cement.

Use only a little cement, and blot any excess immediately.

Sew clean cuts together carefully with nylon thread, using a zigzag stitch over the cut edges.

Don’t pull the thread too tight or the mend will pucker Seal the join with clear nail polish

For ragged cuts or large holes, cut away any damaged screening that remains in the hole.

Cut a patch of fiberglass screening to size it should overlap the hole about 1/2 inch on all sides.

Using nylon thread, sew the patch carefully into place, using a firm but not tight running stitch Seal the edges of the patch with clear nail polish.

Metal Screen

To close a pinhole in a metal screen, use an ice pick or toothpick to push the bent wires back into place.

If a small opening remains, close it with a dab of household cement or clear nail polish.

Apply nail polish sparingly and let dry, repeat until the opening is filled.

Sew long tears together with a needle threaded with line wire Seal the mend with clear nail polish

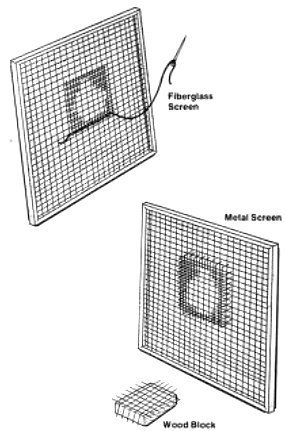

To repair large holes, cut away any damaged wires that remain in the hole.

Cut a square or rectangular piece of screening about 2 inches larger all around than the hole.

Pull away the outside wires on all four edges to a depth of about 1/2 inch to make a fringe of wires on each side.

Bend the fringe wires on each side over a block of scrap wood, making a sharp, even, right-angle bend all around the patch.

Position the patch over the hole.

Press firmly and evenly on the patch to push the bent fringe wires through the mesh of the screen.

The patch should lie flat and even against the screen.

On the other side of the screen, bend the protruding fringe wires fiat, folding them in toward the center of the patch.

For a more secure patch, stitch around the edge of the patch with fine wire.

Replacing a Damaged Window or Door Screen with a New Screen

When a screen has so many holes, or such big ones, that it isn’t worth patching-or when metal screening becomes bulged and rusted-it’s time to replace the screening entirely.

As long as the frame is in good shape, this isn’t as difficult as it sounds.

If the frame is wood, you can use either fiberglass or fine-mesh aluminum screening: if it’s aluminum, you must use aluminum screening.

You may be able to buy the screening cut to size otherwise, cut it about 1 1/2 inches larger all around than the opening .

If you’re working on an aluminum-framed screen, you’ll also need plastic splining, a few inches longer than the diameter of the screen, to replace the old metal spline.

Replacing a Wood-Framed Screen

To replace a screen in a wood frame, use a stiff putty knife to carefully pry up the molding around the edges.

Be careful not to crack the molding, and leave the brads in place to reattach it later.

When the molding is off, pry out the tacks or staples that held the screening in place, and remove the screening.

Pull out any staples or tacks left in the frame.

If the new screening must be trimmed to fit, lay it over the frame and trace the outline of the opening on it with chalk.

Then cut the screening to size, 11/2 inches larger all around than the traced outline.

It the new screening must be trimmed to fit, lay it over the frame and trace the outline of the opening on it with chalk.

Then cut the screening to size, 11/2 inches larger all around than the traced outline.

To stretch the screening into place in the frame, you must bow or arch the frame.

There are two ways to do this by weighting or clamping in either case, the idea is to bend the frame into a pronounced bow.

To use the weight method, set the frame the long way across two sawhorses, and hang a heavy weight from a rope around the center of the frame.

To clamp the frame into a bow, set it on a workbench or a wide board across two sawhorses.

Place a C-clamp at the center of each long side, holding the frame to the work surface and set a long piece of scrap wood, such as a 2 x 4, between the frame and the work surface at each end.

As you tighten the C-clamps, the frame will bow over the 2 x 4’s.

When the frame is securely clamped, set the screening across it, aligned along one unclamped end.

Use a staple gun loaded with heavy-duty staples to attach the screening to the frame, place the staples at right angles to the frame, about two to three inches apart.

If you’re using fiberglass screening, turn the cut edge under about one inch before stapling it down.

When the first side is securely stapled, pull the loose screening over the clamped frame, and stretch it firmly and evenly across the opposite side.

Holding it firmly as you work, staple the second side into place, setting the staples two to three inches apart at right angles to the frame.

Then unclamp or unweight the frame.

The screening should be pulled very tight as it straightens out.

Staple the other two sides into place, and trim off any excess screening.

To finish the job, replace the molding to cover the stapled edges of the screening

Replacing a Aluminum-Framed Screen Tearing

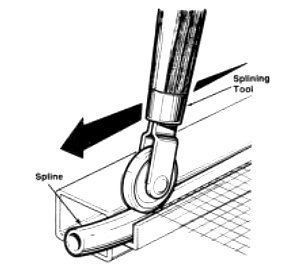

To replace a screen in an aluminum frame, you don’t have to bow the frame, but you’ll need a special splining tool to install the plastic spline.

First pry up the metal spline that holds the old screening in place using a screwdriver or a putty knife, and remove the old screening.

Lay the frame fiat, and position the new screening over it.

Trim the edges so that the screening extends just to the outside edges of the frame.

To keep the screening level with the frame, set scrap boards under it, the same thickness as the frame.

When the screening is trimmed correctly, position it so that one end and one side are lined up on the outside edge of the splining groove in the frame.

Hold the screening carefully in place.

Then, with the convex roller of the splining tool, force the edge of the screening into the splining groove, be careful not to let the screening slip out of place.

Secure the other two sides the same way, stretching the screening taut as you work.

When all four sides of the screening are in place, cut off any excess screening with tin snips.

Then, using the concave end of the splining tool, drive the plastic spline into the groove to hold the screening in place.

Start installing the spline at a comer and work around the frame, where the ends meet, cut off the excess splining.

With the spline in place, your screen is as good as new.

More Screen Tearing Repair Tips

Patching a Screen Tips

To repair a fiberglass screen, take a utility knife and cut out a square patch of the damaged screen just slightly larger than the tear or hole.

Use this cut out patch as a template, and put it on your replacement screen material.

Again, use the knife to cut around the “pattern’ of the damaged screen to get your replacement.

Once you’ve cut that out, put the patch over the hole and use glue to hold it in place.

Just use a fine bead of airplane glue to hold the new patch in place.

For making a patch on an aluminum screen, basically repeat the above steps.

However, once you’ve cut out your aluminum patch, take one thread off all four sides.

This will give you several threads on each side of the patch.

Take the aluminum patch and place it over the hole you’ve cut out.

Then take the threads and bend them, stick them through the aluminum screening and bend all the threads down flat against the screen.

This will hold your aluminum patch in place.

Replacing an Entire Screen Tips

- With a utility knife, use the tip of the blade to lift up one corner of the spline (the rubber tubing that holds the screen inside the frame).

Pull the spline out all the way around the screen frame and remove the old screen. - Take your replacement screening, which comes in rolls, and lay it out over your screen frame.

Use the utility knife to cut the screen into a rough fit, leaving about 2″ – 3″ of excess screen overhanging the frame. - Now take the spline (you can either use the old spline or install new spline) and reinstall it.

Put one end of the spline into one corner of the frame (there’s a channel in the screen for the spline) and simply use the screen roller to mash the spline into the channel.

As you go around the screen, the spline will actually tighten the screen (much like a skin over a drum) for a nice fit. - When you’re finished putting spline in around the frame, take your utility knife and cut away any of the excess screen.