Planing end grain is more difficult than planing the face or edge with the grain because, in planing the end, you will actually be cutting off ends of the fibers.

This difficulty necessitates an extremely sharp plane iron.

When the stock to be planed can be locked in a vise, a jack plane is used. For other jobs, the block plane is satisfactory.

The Block Plane

For a primer on types of planes, assembling, and adjusting hand planes, check out the Assembling and Adjusting Hand Planes article.

The block plane is much smaller than the jack plane.

It has a single plane iron which is placed in the plane with the beveled side up.

The plane iron also rests in the plane at a much lower angle than the iron in a regular plane.

This makes it possible to cut end grain more efficiently.

As you can see, this particular plane has no lateral adjustment, but only an adjusting screw to regulate the depth of cut.

However, some block planes do have a lateral adjustment.

Adjusting the Block Plane

The block plane is adjusted in the same manner as other planes, except when there is no lateral adjusting lever.

To make this adjustment, loosen the plane iron cap and sight along the bottom of the plane.

Then, with your fingers, press the plane iron to the right or left until it is parallel to the bottom of the plane.

Tighten the lever cap screw.

The depth adjustment is made in the same way as for other types of planes.

Using the Block Plane to Plane End Grain

For a primer on general hand planing of surface, check out the How to Hand Plane a Surface article.

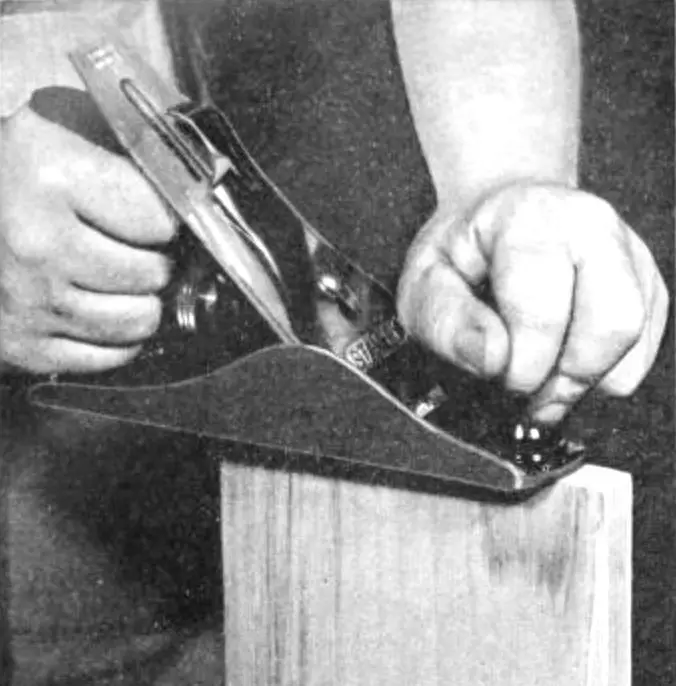

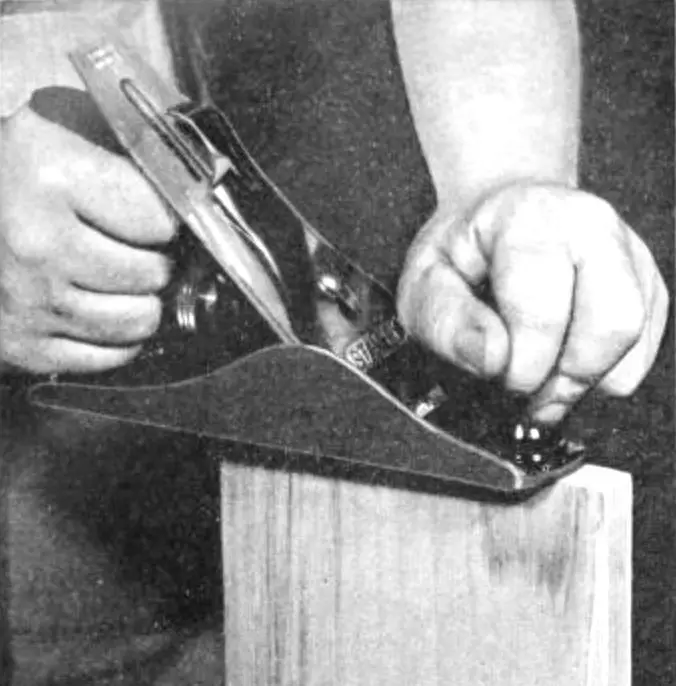

Hold the block plane in your right hand with the thumb on one side, the forefinger over the finger rest, and the other three fingers on the other side.

Begin from one edge to work toward the center.

Begin from the other edge, doing the same.

Take pains to hold the block plane square with the work.

You will find that it takes considerable pressure to cut the end grain.

It is best to take a shallow cut to keep the plane from jumping instead of cutting smoothly.

The block plane is also used for planing with the grain, especially in model work.

Planing End Grain with a Jack Plane

Make sure that the plane iron is very sharp and that the plane iron cap is set very close to the cutting edge, not over 1/32 of an inch.

Lock the stock firmly in the vise with the end protruding slightly.

In planing end grain, it is not possible to go completely across the end, as this will split out the wood.

Therefore one of the following three methods should be followed:

- Plane about halfway across the stock. Then lift the handle of the plane slowly. Begin at the other end to do the same thing. Check for squareness with the working face and working edge.

- Plane a short bevel on the waste edge of the stock and then begin from the other side to plane all the way across.

- Secure a piece of scrap stock exactly the same thickness as the piece you are working on and lock it in the vise just ahead of the finished piece so that you actually have extended the end grain. Then you can plane all of the way across the end grain without fear of splitting out the piece.

Whichever method is used, frequently check the end grain from both the working face and working edge to make sure that it is square.

Hand Planing End Grain Review

Here are some questions you can use to test your knowledge of the previous article:

- What makes end grain so difficult to plane?

- How is a block plane different from other planes?

- When would you choose a block plane to plane with the grain?

- What are the three methods of planing end grain?